You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

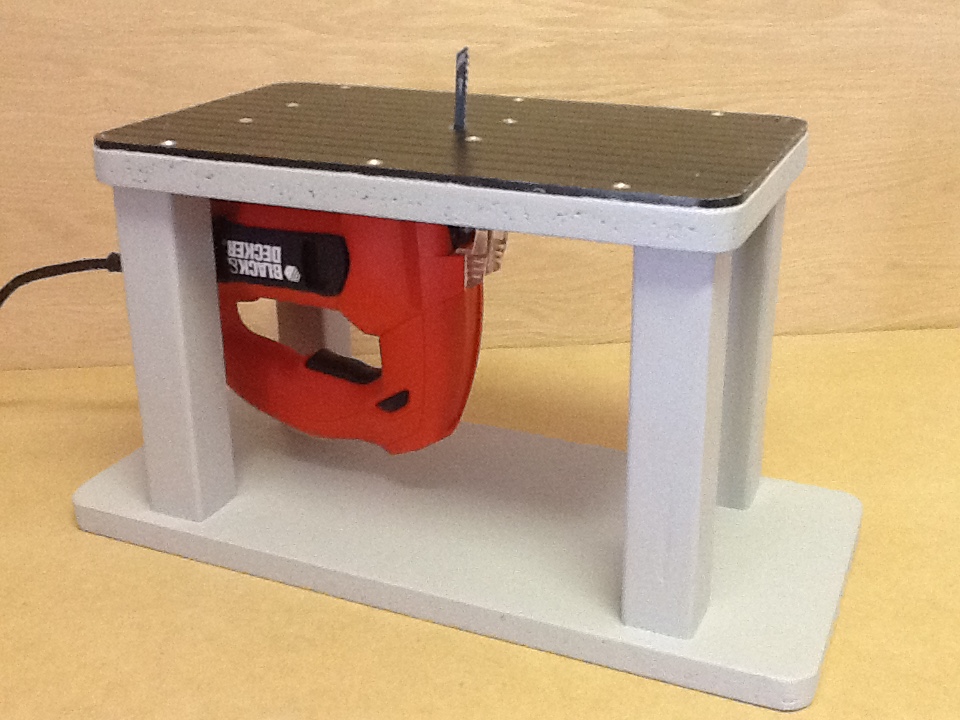

Table top jigsaw mount

- Thread starter DavidRam

- Start date

This is the mechanism that keeps the bandsaw blade straight. I'm thinking it would be tough to replicate with a jigsaw, since you already have limited length of the blade, factoring in the stroke.

But I can think of a passive way to ensure perfect vertical:

If you buy a laser pointer (you'll probably need to disassemble it, if not to mount it, to replace the switch with one that's not momentary) you could suspend it so it points right down perfectly on the tip of the blade.

When cutting curves, if the blade flexes, you'd see the blade move away from the laser pointer dot and you'd know to slow down or adjust.

Just an idea.

Sent from my LM-G710 using Tapatalk

But I can think of a passive way to ensure perfect vertical:

If you buy a laser pointer (you'll probably need to disassemble it, if not to mount it, to replace the switch with one that's not momentary) you could suspend it so it points right down perfectly on the tip of the blade.

When cutting curves, if the blade flexes, you'd see the blade move away from the laser pointer dot and you'd know to slow down or adjust.

Just an idea.

Sent from my LM-G710 using Tapatalk

This was my attempt to make that router table with vacuum chamber, as built into little table saw.

You can probably see where I got a crack that started on the front edge, because it's just pegboard on top (there's bracing and a structure inside, made from MDF - see the chamber poking out below). Besides that, it works. That vacuum hose on the floor hooks up to a port on the bottom.

But you can see on my garage full size table saw, I have a lot more room I could build one.

Plus I could either plug in my shop vac up there, or not even worry about dust since I could be in my driveway.

Maybe in spring I'll think about it again.

Sent from my LM-G710 using Tapatalk

You can probably see where I got a crack that started on the front edge, because it's just pegboard on top (there's bracing and a structure inside, made from MDF - see the chamber poking out below). Besides that, it works. That vacuum hose on the floor hooks up to a port on the bottom.

But you can see on my garage full size table saw, I have a lot more room I could build one.

Plus I could either plug in my shop vac up there, or not even worry about dust since I could be in my driveway.

Maybe in spring I'll think about it again.

Sent from my LM-G710 using Tapatalk

This is the mechanism that keeps the bandsaw blade straight. I'm thinking it would be tough to replicate with a jigsaw, since you already have limited length of the blade, factoring in the stroke.

But I can think of a passive way to ensure perfect vertical:

If you buy a laser pointer (you'll probably need to disassemble it, if not to mount it, to replace the switch with one that's not momentary) you could suspend it so it points right down perfectly on the tip of the blade.

When cutting curves, if the blade flexes, you'd see the blade move away from the laser pointer dot and you'd know to slow down or adjust.

Just an idea.

Sent from my LM-G710 using Tapatalk

You could use bearings https://www.youtube.com/watch?v=wFnbcOLF4qU&ab_channel=JSK-koubou

I skipped ahead -

I didn't catch if the whole arm was vertically adjustable on that, but would be doable with slotted holes and thumb nuts with washers under them.

Looks like you could leave yourself the ability to cut material at least an inch thick with a standard blade - I wonder if there's like a 4" (or longer) blade that might allow you to cut something thick like a 2x4.

I bet there is.

Sent from my LM-G710 using Tapatalk

I didn't catch if the whole arm was vertically adjustable on that, but would be doable with slotted holes and thumb nuts with washers under them.

Looks like you could leave yourself the ability to cut material at least an inch thick with a standard blade - I wonder if there's like a 4" (or longer) blade that might allow you to cut something thick like a 2x4.

I bet there is.

Sent from my LM-G710 using Tapatalk

Grinder

Active member

Yes. And yes. Both are shown in the video.I skipped ahead -

I didn't catch if the whole arm was vertically adjustable on that, but would be doable with slotted holes and thumb nuts with washers under them.

Looks like you could leave yourself the ability to cut material at least an inch thick with a standard blade - I wonder if there's like a 4" (or longer) blade that might allow you to cut something thick like a 2x4.

I bet there is.

Sent from my LM-G710 using Tapatalk