My client wanted to make a change to his a pillars so that he could further optimize the sound and give them a nice style in the process. He had seat rails installed for competition so this greatly changed the listening position and affected his near side hf response. After taking some time to test and listen to the drivers in various positions from the new listening position, I came up with a design that was modular and would allow us to get the tweeter positioned where it sounded best. I designed the 2 piece baffle and then used Apicella Autosound's new baffle laser cutting service to get my parts cut out.

The drivers. Accuton C30 and C168

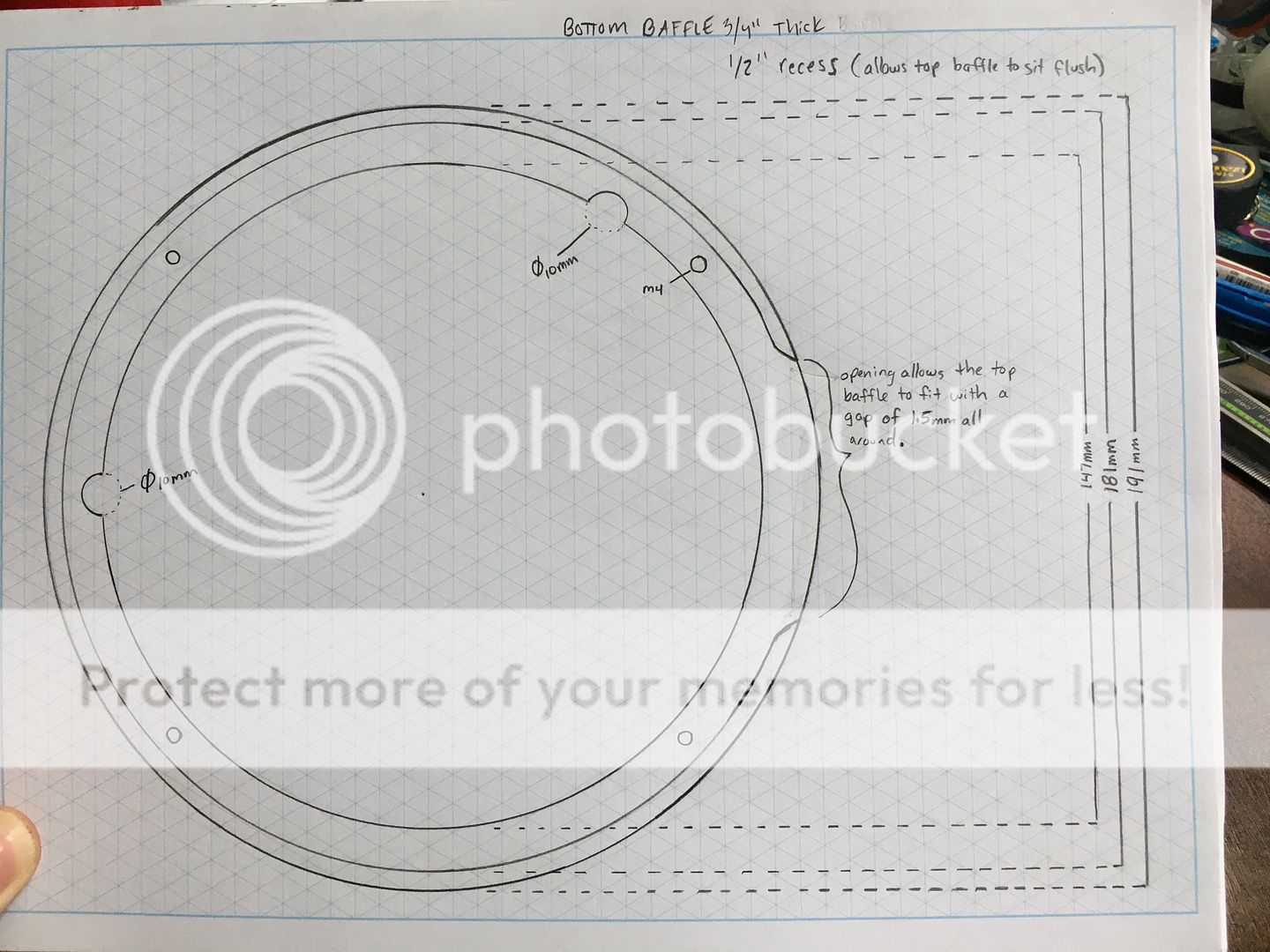

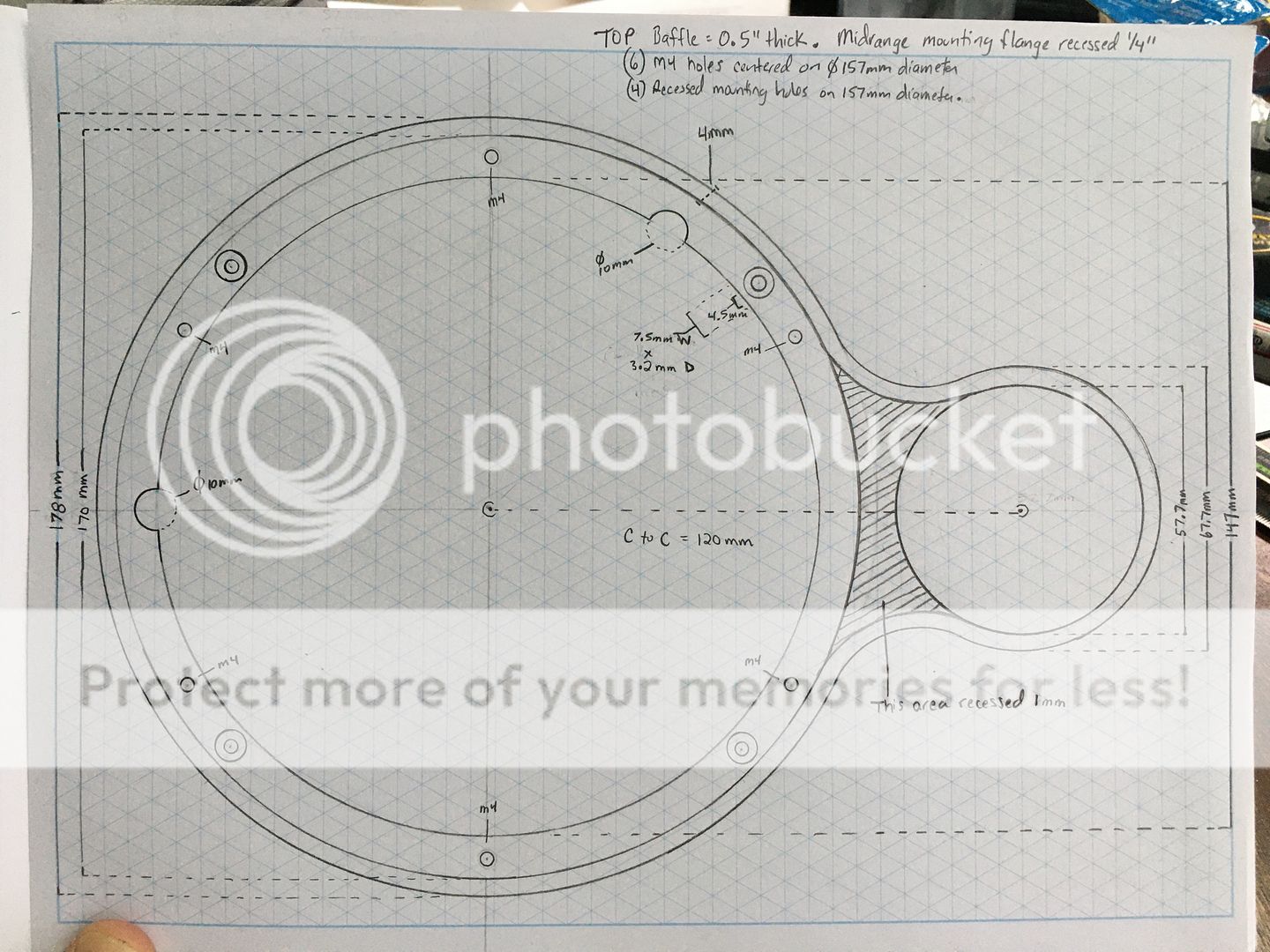

2 piece baffle design

Some of the laser cut acrylic pieces ordered from Apicella Autosound for this project:

Masking and fiberglassing the molds (I did not build off of an existing plastic panel, I molded and created new ones from scratch).

- Forum

-

Affiliated Stores

- Amazon

- Walmart

- Sam's Club

- Parts-Express

- Sonic Electronix

- MonoPrice

- The Home Depot

- Lowe's

- Crutchfield

- ebay

- AliExpress

- Best Buy

- Newegg

- Tiger Direct

- Acer

- Advance Auto Parts

- JC Whitney

- Zoro

- Tractor Supply Co

- Bed Bath and Beyond

- Woodcraft

- Bass Pro Shop

- Academy Sports and Outdoors

- Palmetto State Armory

- 5.11 Tactical

- 4-Wheel Parts

- Harry's Shave and Grooming

- Dollar Shave Club

- My Threads

Reply With Quote

Reply With Quote