I will start with, this is way harder than I expected...

Vehicle:

2007 GMC Yukon XL 2500

Bought with:

Custom rims, tint, leveling kit, 4-Concept head rest DVD/monitors(I added these)

Goals:

2 things were immediately clear when I got this truck in January. It is noisier driving down the road than my 03 Denali XL was, and the stereo is much worse. My expectations started from the idea that I could quiet road noise and make the stereo sound better at the same time. I found a few car audio forums that I became immersed in, acquainting myself with products and ideas surrounding SQ in vehicles while silently lurking. Ultimately a few goals came about while learning how I wanted to approach the build:

- Reduce road noise and kill as many rattles as I can locate(there are a lot!)

- Achieve the best possible SQ within the limitation of factory front speaker locations, aiming and budget. Factory Bose rears for kiddie movies while traveling only

- Full factory appearance/Stealth installation (possible exception for tweeter grills)

- Smiling with pride driving down the road listening to excellent sound without so much road/wind noise.

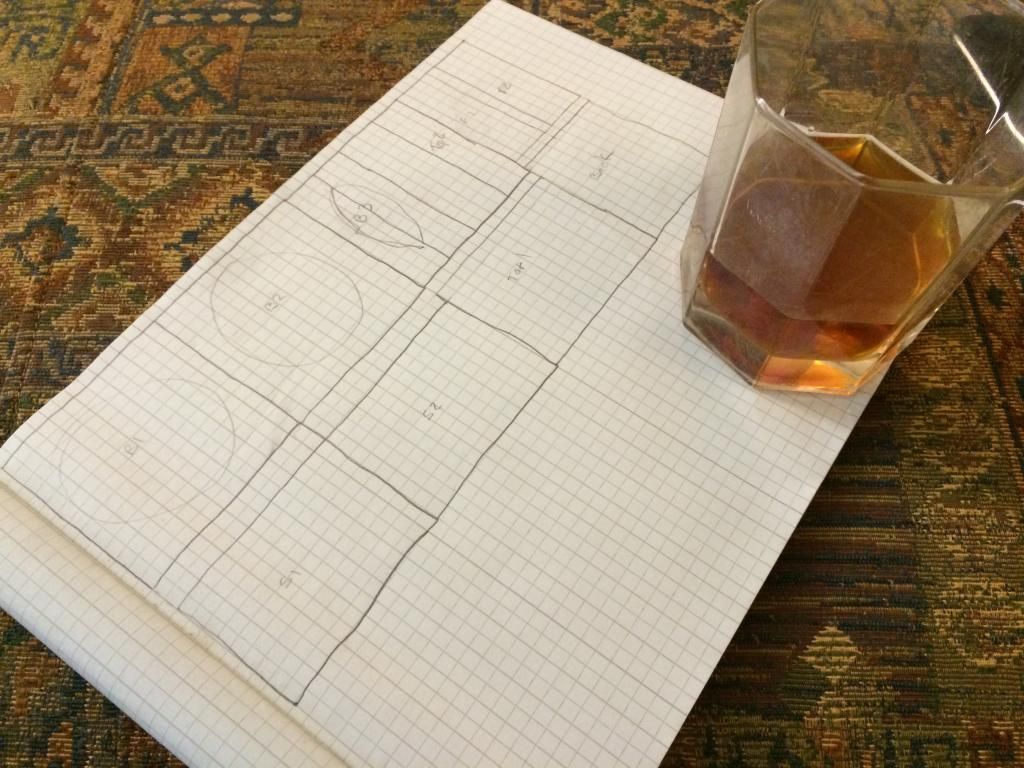

Design Concept:

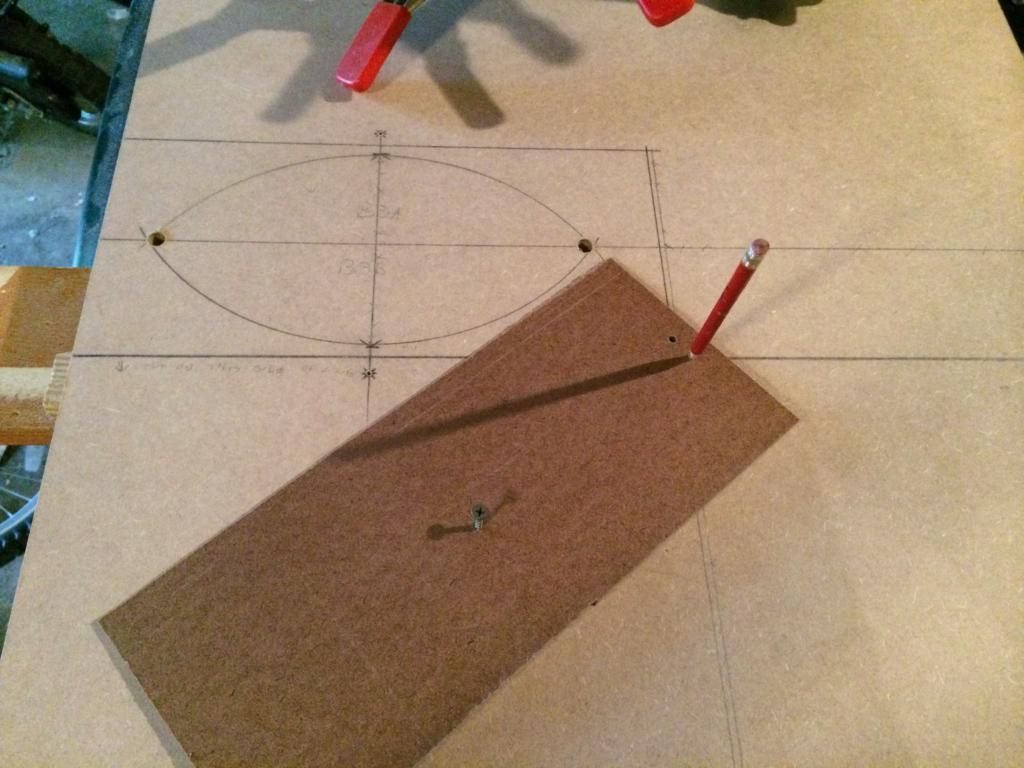

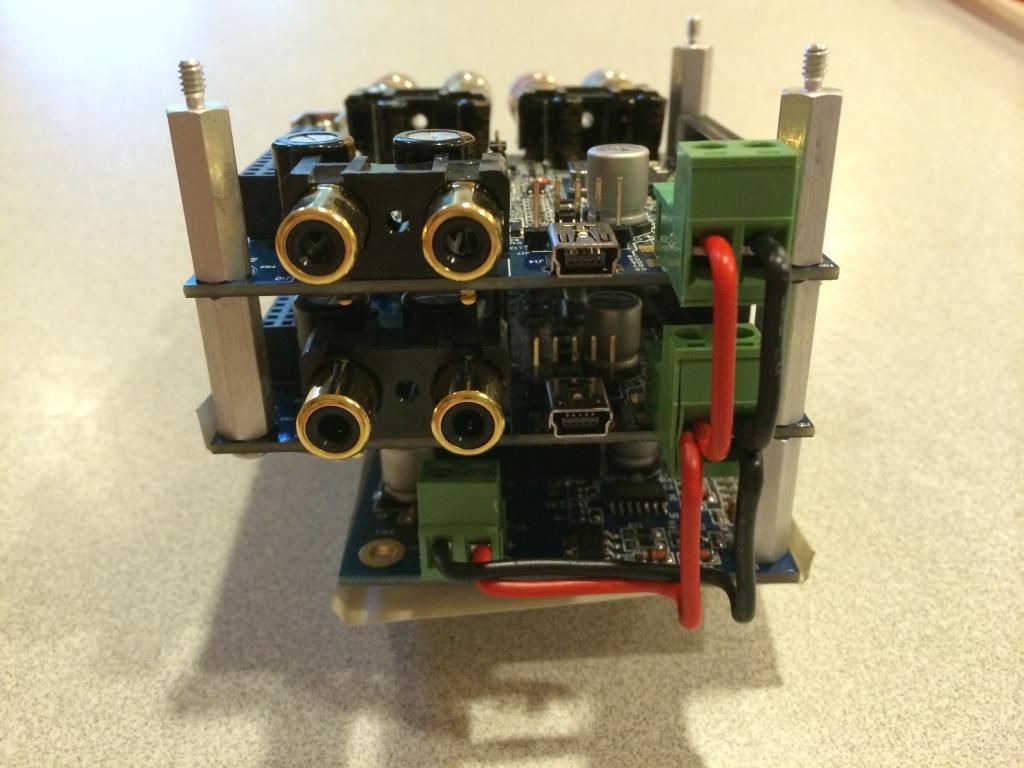

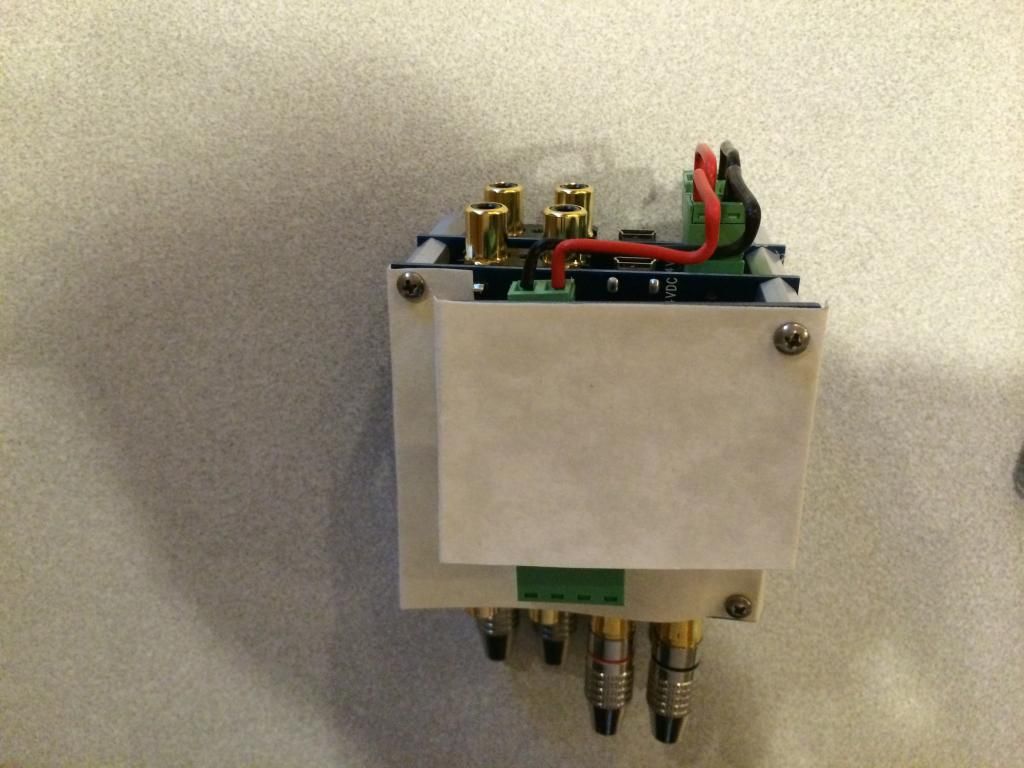

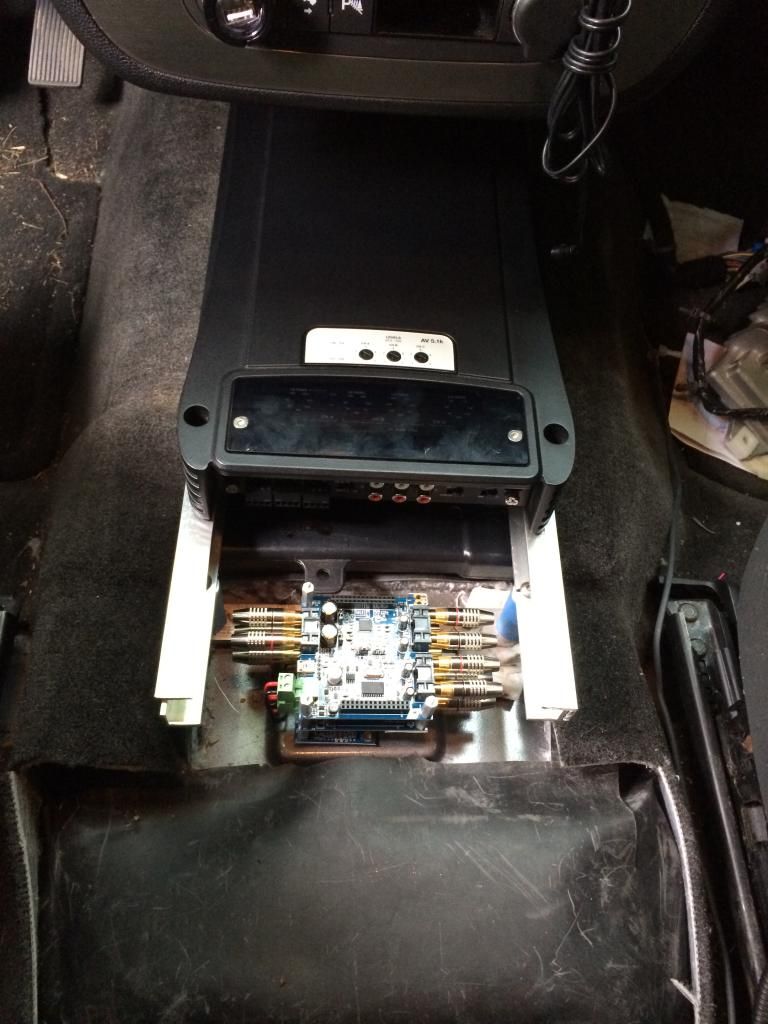

The design concept revolves around the goal of a fully stealth install, with no visual cues anything is in there, 2-way active with no usable rear fill and a single 5 channel amp. I had come to terms that I would have to put an amp under the middle row seat until I took out the console and stared at it for a few days on and off. I dismantled the console completely and was left with a flimsy shell, but a ton of space. After doing some measuring, I felt confident that not only would the sub box fit in there, but also the amp and dsp. The key is building a strong console skeleton to replace the frame that I am discarding. Granted I am losing a huge cubby in the console, but all I put in there is stuff that I don't need or use, so for me, the space removed just removes clutter from the truck. So all that to say, the plan is all XBL2 Drivers w/Amp, DSP and Sub located in the center console.

Budget:

I will document all encompassing costs and hours worked on the build as they come along for reference.

$2000 + my "free" labor time

5-10% Sound Control

5-10% Installation, Sub Box, and Accessories

10-15% Source and Processing

35-40% Amplification

30-35% Speakers

For 12+ weeks prior to the start of the build I spent about 75 hours, by my best guess, researching and analyzing information, mostly at the "other" place to create some goals, a budget, design concept and gear selections. Now I am about ~12 weeks into the build with quite possibly 12 more to go...

The following posts are my build log/journal of the process...

Help for Search Bots: 2008 2009 2010 2011 2012 Suburban Tahoe Silverado Avalanche Escalade

- Forum

-

Affiliated Stores

- Amazon

- Walmart

- Sam's Club

- Parts-Express

- Sonic Electronix

- MonoPrice

- The Home Depot

- Lowe's

- Crutchfield

- ebay

- AliExpress

- Best Buy

- Newegg

- Tiger Direct

- Acer

- Advance Auto Parts

- JC Whitney

- Zoro

- Tractor Supply Co

- Bed Bath and Beyond

- Woodcraft

- Bass Pro Shop

- Academy Sports and Outdoors

- Palmetto State Armory

- 5.11 Tactical

- 4-Wheel Parts

- Harry's Shave and Grooming

- Dollar Shave Club

- My Threads

Reply With Quote

Reply With Quote

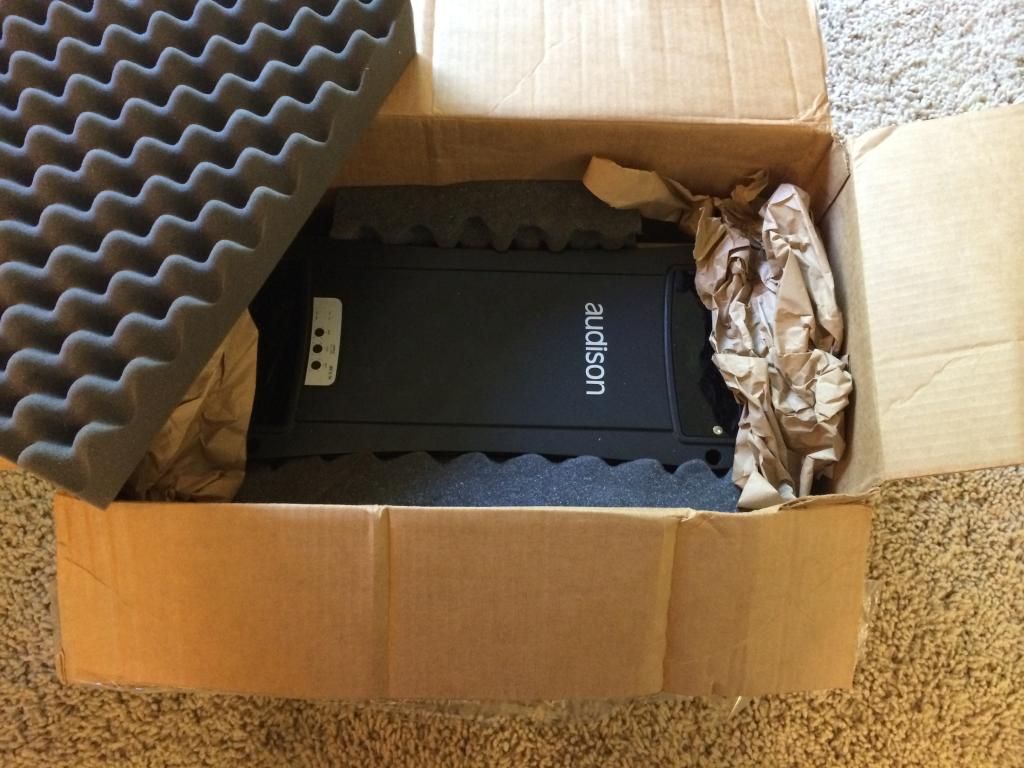

This amp came up for sale on the "other" place and I threw out an offer of $675 and just like that, I end up the owner of an audison amp. Thanks to BumpinJetta and JKnight for organizing the deal, I wouldn’t hesitate to do it again.

This amp came up for sale on the "other" place and I threw out an offer of $675 and just like that, I end up the owner of an audison amp. Thanks to BumpinJetta and JKnight for organizing the deal, I wouldn’t hesitate to do it again.