Since my buddies are over here and I totally forgot I didn't post here, I'll carry over my current project from *elsewhere*.

After some deliberation and gear swapping, I finally decided to build a set of speakers that I want as opposed to just holding myself over with something that was close to what I wanted. For about $500 more than what I had in my passive Kef R500 towers, I'll be able to build a fully active 3-way setup with the following gear:

- Kef R-Series concentric mid/tweeter

- Scanspeak 26w/8867T 10” woofer.

- Rane RPM26z for processing (crossover and EQ)

- Crown DriveCore XLS1500 for tweeters (525w x2 @ 4ohm)

- Crown XLS2000 for mids (650w x2 @ 4ohm)

- Crown XLS2500 for woofers (775w x2 @ 4ohm)

Total power overkill, I know, but I had a couple already and I see no downside to using them. Talk about headroom… sheesh!

Initially, I had planned to use dual woofers per tower. This was intended to keep the driver within beaming at the crossover but also allow me the abillity to smooth the LF response with the 2nd woofer. As the testing and simulations went on, I realized that using a single 10” would behoove me in regards to vertical polar and strike a nice balance for where I intended to cross thanks to the mid’s lower frequency limits and the woofer’s higher frequency limits, combined with baffle step. Ultimately, I plan to have the crossover between the woofer and concentric mid in the neighborhood of 400-500hz. I may still be lacking in regards to the LF smoothness, but it's a tradeoff I'm willing to take.

I’m really not a fast worker when it comes to wood. I’m not a fan of building anything because I can’t achieve the ‘measure twice, cut once’ aspect. With that said, this build really will be simple at least with respect to the cabinet. I wanted to go with curved cabs but I was worried I’d spend more time and money buying materials than I have at my leisure, it’d make more sense to start with a very KISS method and possibly revisit a more complex, but aesthetically pleasing tower design this summer when I have time.

Each cabinet is 12x13x48. This size was chosen in order to achieve a baffle step between the woofer and mid at about 500hz. Again, I’m just assuming that doing so allows for a more natural driver response without the need to put any correction in to the system. Of course, the 10” woofer size really drives the necessary baffle width… I suppose it all just sort of fell together in this regard. The woofer height will be placed about 23” from the floor. This height was chosen as it helps me stay within some reasonable range of lobing limits in conjunction with being at a good frequency with respect to floor bounce. The concentric will be placed roughly 41” from the floor. This height was chosen because that’s approximately where my head will be. There’s nothing I can’t stand more than looking down on a speaker at a normal seated height. It totally kills my psyche, man.

I did a klippel test on each woofer to obtain large and small signal parameters. Small signal specs indicate a sealed enclosure size of 0.75ft^3 to hit a Qtc of 0.707, though my measurements showed different. Ultimately, based on my measurements, I arrived at a sealed volume of about 1.75ft^3. This puts the Qtc at about 0.60. Namely, however, it gives me some play room and by adding or removing stuffing, I should be able to achieve a Qtc that I desire. The upper section, where the midrange concentric will be housed was not targeted for any particular Qtc. I did, however, model up the enclosure size I plan to use (simply by default of bracing location and cabinet size) and found the f3 to about 213hz. This is less than half of the desired crossover point, so I think Im OK here. I wanted the extra room in the enclosure to be able to stuff it with varying materials. A target Qtc isn’t important to me here. Though, managing the internal reflections is.

On to the build...

I went to a local lumber yard to look at their Birch offerings. $65/sheet for domestic. And it looked good. The problem was they wouldn’t cut the sheet in half for me to fit in my civic. And they closed soon which meant borrowing a truck wasn’t going to happen and I wanted to get started the next day and work on the project during the weekend. I went to the local Home Depot and found they sell 12x48” MDF shelving pieces for about $5/sheet. These were practically perfect for me. $75 later I drove back home with a stack of 13.

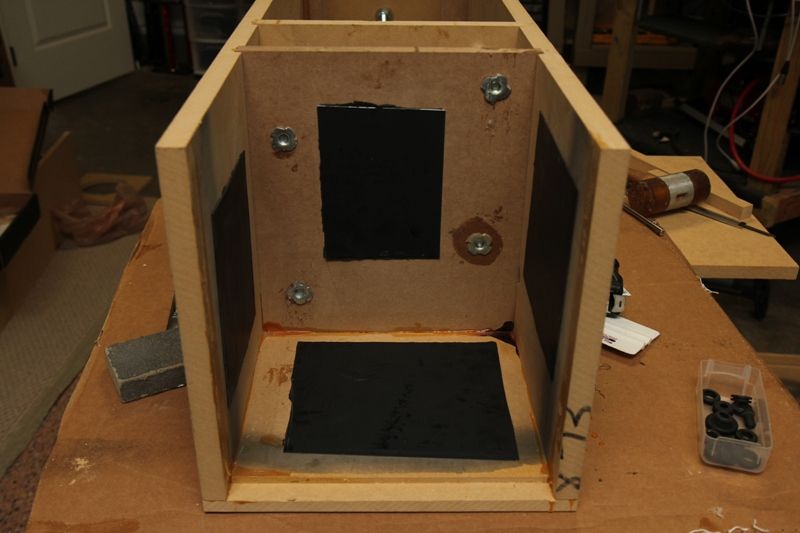

All said and done, I didn’t get too far this weekend. I did manage to cut dados in the main structure pieces for both enclosures to support the 4 braces I plan to have. In my first time ever using a dado, I learned a couple things. So, if you look closely you’ll probably see some bad spots where those lessons were learned.

I also took a scrap piece of birch and cut some practice holes for the drivers so I’d know exactly what size the OD, ID, and depth was in order to flush mount them. Pictures are below.

Sawdust sucks! Thank goodness for respirators.

- Forum

-

Affiliated Stores

- Amazon

- Walmart

- Sam's Club

- Parts-Express

- Sonic Electronix

- MonoPrice

- The Home Depot

- Lowe's

- Crutchfield

- ebay

- AliExpress

- Best Buy

- Newegg

- Tiger Direct

- Acer

- Advance Auto Parts

- JC Whitney

- Zoro

- Tractor Supply Co

- Bed Bath and Beyond

- Woodcraft

- Bass Pro Shop

- Academy Sports and Outdoors

- Palmetto State Armory

- 5.11 Tactical

- 4-Wheel Parts

- Harry's Shave and Grooming

- Dollar Shave Club

- My Threads

Reply With Quote

Reply With Quote

But, as sad as it is, I'm actually REALLY looking forward to the bondo/Rage Gold sanding phase on these. That means I'm closer to the end and those spots should clean up. Anything is better than cutting more MDF. I had that stuff all in my beard. Glad I have a respirator because MDF boogers suck!

But, as sad as it is, I'm actually REALLY looking forward to the bondo/Rage Gold sanding phase on these. That means I'm closer to the end and those spots should clean up. Anything is better than cutting more MDF. I had that stuff all in my beard. Glad I have a respirator because MDF boogers suck!